In-situ neutron imaging of hydrogen storage systems

by Łukasz Gondek and Nikolay Kardjilov

Hydrogen storage

Hydrogen offers excellent prospects as potential energy carrier, and a lot of effort is being put into the development of technologies allowing to introduce it into common usage [1]. The production and storing of hydrogen, as well as the recovery of the energy, are currently the object of many researchers´ attention, across the world.

However, it seems that the development of hydrogen storage systems is still one step behind the technologies for producing and converting hydrogen into energy. Hydrogen can be stored in several ways, including in high-pressure vessels, liquid hydrogen tanks, metal-organic frameworks (MOF) based on cryogenic bottles, or metal-hydrides systems. For safety as well as technological and economical reasons, metal-hydrides are the most interesting candidates and are being extensively investigated around the world. But their weight capacity remains unsatisfactory, and way below the 10 wt.% (weight percent) of the storage system (achieved under reasonable thermodynamic conditions) considered the threshold for mobile applications such as portable electronics and cars.

The performance of metal-hydride storage systems depends on the selection of an appropriate active material with high capacity, reversibility, and good thermal conductivity. On the other hand, the internal structure of the storage tank must be optimized in order to keep hydrogenation/dehydrogenation kinetics as high as possible. Namely, the heat released upon introducing hydrogen into the metallic bed should be dissipated as the rise of the active material’s temperature leads to the hampering of the hydrogenation reaction.

Although metallic hydride-based storage systems are commonly used and commercially available, the processes occurring inside such devices have been deduced from external parameters, such as changes of H2 pressure or the container’s temperature, characterizing the whole container, rather than directly studied from the container’s interior.

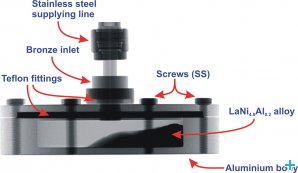

Thanks to the help of our colleagues from the Neutron Imaging Group at BENSC, we carried out in situ imaging of a LaNi4.8Al0.2- based hydrogen storage container, using the cold neutron high-resolution instrument V7-CONRAD at BENSC, Helmholtz Center Berlin. For further information about experimental technique, please visit the instrument’s webpage.

What do neutrons see?

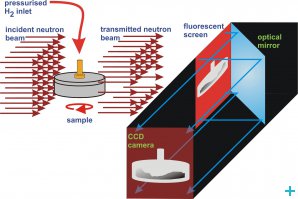

When one thinks of radiography or tomography, X-ray medical imaging is usually the first thing that comes to mind. Although this technique is excellent for imaging the soft-tissues of a human body, it is useless for dense metallic objects a few centimeters thick, due to the attenuation of X-rays, which rises with the atomic number of the attenuator. In contrast to X-rays, neutrons possess properties that make them perfectly suited for the investigation of processes inside hydrogen storage tanks. We performed radiography and tomography experiments on the operating hydrogen-storage tank using CONRAD (see Figure 1 for experimental set-up). Our results show that neutron imaging allows the qualitative as well as quantitative analysis of hydrogen absorption/desorption kinetics, with a spatial resolution of 70 µm (0.07mm). Radiographic image of our container with details of its construction is presented in Figure 2.

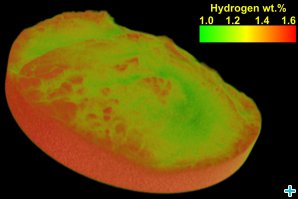

Comparing to other elements (e.g. simple metals), hydrogen has a very high attenuation coefficient; therefore it is possible to track even small quantities of hydrogen within the filling alloy. Thus, we are able to quantitatively visualize, in 3D, the hydrogen distribution upon operation of the container (see Figure 3). We were able to confirm that the hydrogen uptake in the bed (LaNi4.8Al0.2) is enhanced along the aluminium body of the container where heat can be easily transferred. This hints at a crucial role of heat dissipation during the exothermic reaction of hydrogen loading into the bed. Apart from the above, other factors, such as compression of the LaNi4.8Al0.2 powder under the hydrogen pressure applied, were noticed. To conclude, we obtained first-hand information about the complex phenomena taking place inside of the hydrogen storage systems upon operation. It seems that neutron imaging has been under-exploited for the characterization of metal-hydride containers [2]. Complementary imaging using both radiography and tomography may be crucial for the development of more efficient hydrogen storage devices.

References

[1] A. Züttel, A. Borgschulte, L. Schlapbach (Eds), Hydrogen as a Future Energy Carrier, WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim 2008

[2] Ł. Gondek, N. B. Selvaraj, J. Czub, H. Figiel, D. Chapelle, N. Kardjilov, A. Hilger, I. Manke, Int. J. Hyd. Energy 36 (2011) 9751-9757

Dr. Łukasz Gondek is a researcher at the AGH University of Science and Technology in Krakow, Poland and Dr. Nikolay Kardjilov is the V7 instrument scientist at the Helmholtz Center Berlin for Materials and Energy in Berlin, Germany.